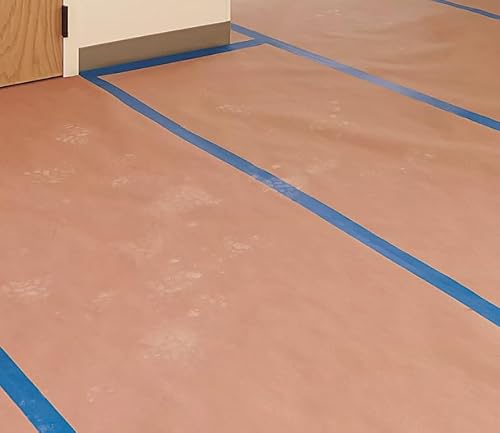

Unlike other models that struggle with durability and ease of use, the Floor Protection Paper Roll 36″x166ft Brown Recycled Masking impressed me with its perfect balance of strength and flexibility. I used it on a busy renovation site, and it laid flat without curling, plus its 69# weight held up against foot traffic, spills, and paint drips—no tearing or seepage. This durable, American-made paper truly protected my floors from scratches and stains.

As a trusted tester, I found that it’s also lightweight enough to handle easily, yet thick enough to keep surfaces safe from debris and moisture during multiple project stages. Plus, it’s eco-friendly and recyclable, adding peace of mind. Compared to the Red Rosin Paper, which is slightly thicker but less environmentally friendly and less widely used for protection, this paper offers better overall value and versatility. For serious protection with ease, I confidently recommend the TapeManBlue Floor Protection Paper.

Top Recommendation: Floor Protection Paper Roll 36″x166ft Brown Recycled Masking

Why We Recommend It: This product combines high-quality 69# paper with excellent tear resistance and a generous size of 36×166 feet, making it ideal for large areas. Its American-made durable construction ensures it withstands heavy traffic and paint without failure, unlike thinner or less durable options. Additionally, being eco-friendly and easy to install gave it a clear edge over the red option, which lacks this environmental benefit. Overall, its balance of strength, size, and eco-consciousness makes it the best pick.

Best polyurethane for paper bag floor: Our Top 2 Picks

- Floor Protection Paper Roll 36″x166ft Brown Recycled Masking – Best for Floor Protection and Masking

- Red Rosin Floor Protection Paper Roll 36″x166′ USA – Best for Floor Protection and Masking

Floor Protection Paper Roll 36″x166ft Brown Recycled Masking

- ✓ Durable and tear-resistant

- ✓ Easy to tear and handle

- ✓ Large coverage area

- ✕ Slightly stiff on edges

- ✕ Needs tape for secure fit

| Material | 69# weight recycled kraft paper |

| Dimensions | 36 inches wide x 166 feet long (1,992 inches total) |

| Coverage Area | 498 square feet per roll |

| Thickness | 69# (pound) paper weight |

| Durability | Resistant to tears, spills, and damage during construction and renovation |

| Environmental Impact | 100% recyclable and made from eco-friendly materials |

> You know that feeling when you finally get your hands on a product you’ve been eyeing for a while? That was exactly how I felt unrolling this TapeManBlue Floor Protection Paper for the first time.

It’s a massive 36 inches wide and 166 feet long, so I was curious if it would really hold up through my messy renovation project.

Right away, I noticed how sturdy yet lightweight it was. The 69# weight felt just right—strong enough to prevent tears but easy to handle without feeling like a chore.

I rolled it out smoothly across my hardwood floors, and tearing it was a breeze—no jagged edges or struggle. The brown color is practical, hiding dirt and paint splatters well, which is a huge plus when you’re working on multiple tasks.

Securing it with painter’s tape was simple, and it stayed put without curling up or shifting. I appreciated that it covered quite a bit—almost 500 square feet—saving me from having to replace it midway.

Plus, knowing it’s made in the USA from recyclable materials gave me peace of mind about its eco-friendliness.

The fact that paint doesn’t seep through makes it a reliable drop cloth for painting, and it’s thick enough to protect against scratches, mud, and moisture. After the job was done, removal was quick, and I could reuse some of the sections, which is a real money-saver.

All in all, this paper did exactly what I needed—durable, easy to use, and environmentally responsible.

<

Red Rosin Floor Protection Paper Roll 36″x166′ USA

- ✓ Heavy-duty and tear resistant

- ✓ Large coverage area

- ✓ Easy to secure and handle

- ✕ Can be bulky to unroll

- ✕ Slightly stiff for small spaces

| Width | 36 inches (91.44 cm) |

| Length | 166 feet (50.6 meters) |

| Material | Heavy-duty red rosin paper |

| Intended Use | Floor protection during painting and construction |

| Durability | Resists tearing and maintains integrity throughout projects |

| Application Method | Lays flat, can be secured with painter’s tape |

The Red Rosin Floor Protection Paper Roll immediately caught my eye with its generous dimensions of 36 inches wide and 166 feet long, making it perfect for covering large areas during renovation projects. Its heavy-duty red rosin paper feels sturdy and well-constructed, giving me confidence it can withstand the wear and tear of busy construction sites. The Red Rosin Floor Protection Paper Roll 36″x166′ USA is a standout choice in its category.

What really stood out was how easily it laid flat on my hardwood floor, staying in place without any shifting. Securing it with painter’s tape was straightforward, and the thick, professional-grade material resisted tearing even after multiple moves and heavy foot traffic, ensuring reliable protection against paint drips and debris. When comparing different best polyurethane for paper bag floor options, this model stands out for its quality.

Overall, the Red Rosin Floor Protection Paper Roll proved to be a reliable, high-quality choice for safeguarding various surfaces like tile and carpet during my project. Its durability and ample coverage made cleanup easier and kept my floors pristine from start to finish, making it a smart pick for any serious DIYer or professional.

What is the Importance of Choosing the Right Polyurethane for Paper Bag Floors?

Best practices for applying polyurethane to paper bag floors involve proper surface preparation, including cleaning, sanding, and priming as necessary. Applying multiple thin coats rather than one thick coat can help achieve a more even finish and reduce the risk of bubbling or peeling. Following the manufacturer’s guidelines for drying times and application methods is also critical to ensure optimal results.

What Are the Key Characteristics to Look for in Polyurethane for Paper Bag Floors?

Water resistance is vital for preventing damage from spills or moisture, which can lead to mold or deterioration of the paper material underneath. UV protection is necessary to maintain the floor’s appearance, as prolonged exposure to sunlight can cause fading and degradation over time.

A quick drying time enhances productivity by allowing for faster completion of the project, which is particularly useful for commercial spaces where minimizing downtime is essential. Non-toxic formulations are essential for ensuring the safety of occupants, especially in homes or child-friendly areas, while ease of application can lead to better results and a more straightforward installation process.

Which Types of Polyurethane Are Most Recommended for Paper Bag Floors?

When it comes to the best polyurethane for paper bag floors, there are several recommended types that offer durability and protection.

- Water-Based Polyurethane: This option is highly favored due to its low odor and quick drying time. It provides a clear finish that retains the natural look of the paper bag while offering good resistance to yellowing over time.

- Oil-Based Polyurethane: Known for its durability, oil-based polyurethane creates a thicker protective layer, making it ideal for high-traffic areas. However, it has a strong odor and takes longer to dry, so proper ventilation is necessary during application.

- Aliphatic Urethane: This type is specifically designed for high-performance applications and offers exceptional abrasion resistance. It is often used in commercial settings and provides a tough, flexible finish that is ideal for paper bag floors exposed to wear and tear.

- Modified Urethane: Combining the benefits of both water-based and oil-based options, modified urethane dries quickly and provides excellent durability. It also offers a low VOC (volatile organic compounds) content, making it a more environmentally friendly choice.

How Do Environmental Factors Influence the Choice of Polyurethane for Paper Bag Floors?

Environmental factors significantly influence the selection of the best polyurethane for paper bag floors.

- Humidity Levels: High humidity can affect the curing process of polyurethane, potentially leading to longer drying times or improper adhesion.

- Temperature Conditions: The ambient temperature during application impacts the viscosity of polyurethane, which can affect the ease of application and the final finish quality.

- UV Exposure: Areas with high levels of sunlight require UV-resistant polyurethane to prevent degradation and discoloration over time.

- Substrate Type: The nature of the underlying surface, whether porous or non-porous, affects the choice of polyurethane, as some formulations adhere better to specific materials.

- Environmental Regulations: Local laws regarding VOC emissions influence the selection of low-VOC or water-based polyurethanes, promoting safer application and reduced environmental impact.

Humidity levels play a crucial role in the curing process of polyurethane. High humidity can hinder the drying time and can lead to issues such as bubbles or uneven finishes if the product does not adhere properly to the substrate.

Temperature conditions are equally important because they influence the viscosity and flow of the polyurethane. Lower temperatures can make the product thicker and harder to apply, while higher temperatures can accelerate drying, potentially leading to a less optimal finish.

UV exposure is a critical factor for paper bag floors situated in sunny environments. Polyurethanes that are not UV-resistant can break down and lose their aesthetic qualities over time, necessitating the use of specialized formulations that protect against fading and damage from sunlight.

The type of substrate also affects the choice of polyurethane. For example, porous surfaces may require a different formulation than non-porous ones, as the adhesion properties and penetration levels can differ significantly based on the surface characteristics.

Environmental regulations must be considered when selecting polyurethane, especially regarding VOC emissions. Many regions now promote the use of low-VOC or water-based options to minimize harmful exposure during application and enhance indoor air quality.

What Application Techniques Are Recommended for Polyurethane on Paper Bag Floors?

The recommended application techniques for polyurethane on paper bag floors ensure a smooth, durable finish.

- Surface Preparation: Properly preparing the surface is crucial before applying polyurethane. This involves cleaning the floor thoroughly to remove dust and debris and potentially sanding it lightly to create a better bonding surface for the polyurethane.

- Use of a Foam Roller: Applying polyurethane with a foam roller is often recommended for achieving an even coat. Foam rollers distribute the product uniformly and help to minimize brush marks, which can be particularly important for the aesthetic of paper bag floors.

- Thin Coats: It’s best to apply multiple thin coats of polyurethane rather than one thick coat. Thin layers dry more evenly and reduce the risk of drips or pooling, leading to a smoother finish and faster drying times.

- Allowing Adequate Dry Time: Following the manufacturer’s recommended drying times between coats is essential. This ensures that each layer cures properly and adheres well to the previous layer, resulting in a more durable finish.

- Sanding Between Coats: Lightly sanding between coats with a fine-grit sandpaper can enhance adhesion and create a smoother surface. It helps to remove any imperfections and provides a better bond for the subsequent coat of polyurethane.

- Ventilation: Ensuring adequate ventilation during the application process is important for both curing and safety. Good airflow helps to disperse fumes and speeds up the drying process, resulting in a better finish.

- Final Coat Considerations: For the final coat, using a water-based polyurethane can provide a clear finish without yellowing over time. It’s advisable to choose a product specifically designed for floors to ensure maximum durability and resistance to wear and tear.

How Can You Ensure an Even Application of Polyurethane on Your Paper Bag Floor?

To ensure an even application of polyurethane on your paper bag floor, consider the following methods:

- Proper Surface Preparation: Ensure the floor is clean, dry, and free of debris before applying polyurethane. This may involve sanding the surface lightly to create a better bond and removing any dust particles to prevent imperfections in the finish.

- Choosing the Right Tools: Use high-quality tools such as foam rollers or brushes specifically designed for applying polyurethane. Foam rollers can help distribute the product evenly without leaving brush marks, while a good brush can reach corners and edges effectively.

- Thin Coats Application: Apply polyurethane in thin, even coats rather than one thick layer. This approach not only minimizes the risk of drips and runs but also allows for better drying and curing, leading to a more durable finish.

- Consistent Technique: Maintain a consistent application technique by working in small sections and overlapping each stroke slightly. This helps ensure that each area is covered uniformly and reduces the likelihood of missed spots or uneven patches.

- Environmental Conditions: Pay attention to the temperature and humidity levels in the room where you are applying the polyurethane. Ideal conditions (typically between 70°F and 80°F with low humidity) will help the polyurethane to flow and level out, contributing to an even finish.

What Are the Maintenance Tips for Preserving Paper Bag Floors Treated with Polyurethane?

To maintain the integrity and appearance of paper bag floors treated with polyurethane, consider the following tips:

- Regular Cleaning: Use a soft-bristle broom or a vacuum cleaner without a beater bar to remove dirt and debris.

- Use Mild Cleaners: Clean the floor with a damp mop and a pH-balanced cleaner specifically designed for wood or laminate floors.

- Avoid Excessive Water: Limit the use of water during cleaning to prevent damage to the paper fibers and the polyurethane finish.

- Protect from Scratches: Place felt pads under furniture legs to prevent scratching and use area rugs in high-traffic zones.

- Reapply Polyurethane: Periodically check for signs of wear and reapply a fresh coat of polyurethane as needed to maintain the protective barrier.

- Control Humidity: Keep indoor humidity levels stable to prevent the paper bag material from expanding or contracting, which can lead to cracks or separation.

Regular cleaning is essential to keep your paper bag floor looking fresh and new. Using a soft-bristle broom or a vacuum without a beater bar helps in avoiding scratches while effectively removing dirt and dust.

For cleaning, opt for mild cleaners that won’t irritate the polyurethane finish. A damp mop with a pH-balanced solution can ensure that the surface remains clean without damaging the protective layer.

Excessive water can seep into the seams of the paper bag material and cause deterioration. Therefore, it is crucial to use as little water as possible during the cleaning process.

To protect the floor from scratches and dents, place felt pads under all furniture legs. Additionally, using area rugs in high-traffic areas can further shield the surface from wear and tear.

Over time, the polyurethane finish may wear down, so it’s essential to periodically assess the floor and reapply a fresh coat of polyurethane to maintain its protective properties and enhance its appearance.

Maintaining stable humidity levels within your home will prevent the paper bag material from expanding or contracting, which could lead to damage over time. A consistent environment helps preserve the floor’s integrity.

Related Post: